A nema connector chart is a visual reference that helps you identify standardized North American plugs and receptacles by their configuration, voltage class, and amperage rating. Instead of guessing whether a plug will fit an outlet or whether a circuit can safely supply a device, the chart gives you a reliable “translation layer” between what you see in your hand and what the electrical system is designed to deliver.

Beginners usually run into NEMA charts when buying a generator cord, setting up a workshop tool, installing a UPS in a small server room, or trying to understand why a “20-amp plug” doesn’t match a “15-amp outlet.” The good news is that NEMA naming follows patterns. Once you learn how to read those patterns, a nema connector chart becomes one of the most practical safety tools you can keep around.

NEMA’s own wiring device standards cover dimensional specifications and configurations for common plugs and receptacles used across residential, commercial, and industrial buildings, which is why the NEMA system shows up everywhere.

What Does NEMA Mean, and Why Do These Charts Exist?

NEMA stands for the National Electrical Manufacturers Association. In the context of connectors, NEMA standards help ensure that plugs and receptacles are manufactured to consistent configurations and ratings so equipment can be connected safely and predictably. The widely referenced standard for many plug and receptacle configurations is ANSI/NEMA WD 6, which covers plugs and receptacles used in typical electrical installations and focuses on dimensional and configuration consistency.

A nema connector chart exists to make those standardized configurations easier to understand in the field. Instead of hunting through specs, you can match a code like “5-15” or “L14-30” to the correct shape and electrical rating.

How to Read a NEMA Connector Chart

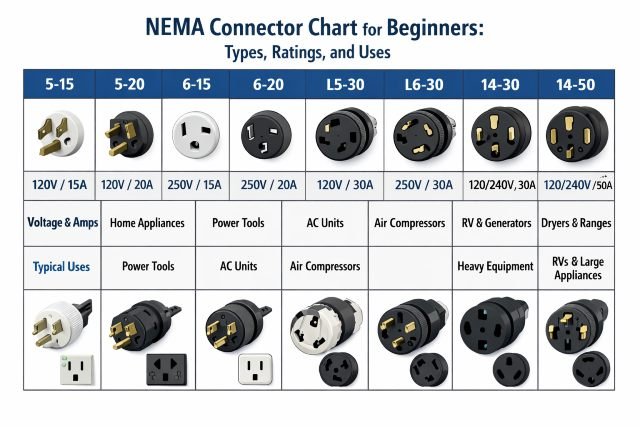

Most charts label connectors using a series like NEMA X–Y or NEMA L X–Y for locking versions. The first number points you toward the voltage class and wiring style family, while the second number is the amp rating.

A classic example is NEMA 5-15, which is the everyday grounded household configuration in many North American homes. Another is NEMA 6-20, often used for certain 240V loads like smaller HVAC components or shop equipment where 20 amps is sufficient. Reference charts frequently show the physical blade pattern alongside the rating so you can visually confirm you’re looking at the right connector.

You’ll also see letters next to codes on many charts. “P” usually denotes a plug, and “R” denotes a receptacle, a convention commonly used on connector chart references.

Understanding Connector Families in a NEMA Connector Chart

Straight-Blade (Non-Locking) Connectors

Straight-blade connectors are the “push in, pull out” style most people recognize. They’re common in homes, offices, and many light commercial spaces. The NEMA 5 family is the one most beginners meet first, and chart references typically show 5-15 and 5-20 prominently because they are the most commonly confused pair.

Twist-Lock (Locking) Connectors

Locking connectors add a twist mechanism to resist vibration or accidental unplugging. On charts, these are usually identified with an “L” prefix, such as L5-30 or L14-30. Locking reference charts often include wiring details like number of wires and poles alongside voltage and amperage.

Higher-Voltage and Multi-Voltage Connectors

Charts also include families built for 240V (and beyond) equipment. In practical terms, this is where you’ll see codes that show up with dryers, ranges, welders, some HVAC gear, and certain data center or IT power use cases. The key is not to rely on “it looks like 240V” as a rule. The chart is what tells you the actual voltage class and compatibility.

Common NEMA Connector Chart Reference Table

The table below is a simplified starter set you can use to orient yourself. Exact use cases vary by equipment and local code, but the ratings and typical applications reflect common chart references.

| NEMA Type | Typical Voltage Class | Amps | Common Context |

|---|---|---|---|

| NEMA 5-15 | 125V | 15A | General household outlets and low-load devices |

| NEMA 5-20 | 125V | 20A | Higher-load 120V circuits in residential/light commercial |

| NEMA 6-20 | 250V | 20A | Some 240V shop tools and smaller HVAC loads |

| NEMA 14-30 | 125/250V | 30A | Many modern dryer-style applications and related equipment contexts |

| NEMA L5-30 | 125V | 30A | Locking 120V use cases including portable power and jobsite setups |

| NEMA L14-30 | 125/250V | 30A | Generators and transfer-switch style setups, locking for stability |

If you want a more exhaustive chart with photos and drawings, use a dedicated plug reference chart and cross-check the configuration naming against NEMA’s WD 6 standard overview page so you’re not relying on a single vendor diagram.

Voltage Ratings: What the Chart Is Really Protecting You From

Voltage matters because plugging a device into the wrong voltage can destroy equipment or create a hazard. A nema connector chart helps prevent mis-matches by making configurations intentionally incompatible across different voltage classes. In plain terms, you’re supposed to be unable to easily plug a 240V-only device into a 120V receptacle, or vice versa, when the correct NEMA devices are used.

When you see references to grounding and bonding requirements in electrical systems, it’s not just theory. The NEC (NFPA 70) includes significant grounding and bonding requirements, and NFPA’s education materials emphasize how important it is to understand grounding and bonding expectations in the Code framework.

For beginners, the practical takeaway is simple: use the nema connector chart to confirm the correct voltage class, and treat grounding as non-optional unless an older legacy installation explicitly dictates otherwise and is addressed properly by a qualified electrician.

Amperage Ratings: Why 15A and 20A Confuse So Many People

Amperage (current) is where beginners often make expensive mistakes. The chart doesn’t just tell you what fits; it tells you what the connector is designed to carry safely. A 20-amp circuit and receptacle system exists because some devices need higher current. If you try to “make it work” using the wrong cords or adapters, you can create overheating conditions.

Safety organizations repeatedly warn about overloading cords and using temporary wiring incorrectly because heat buildup becomes a fire risk over time. ESFI’s extension cord safety guidance highlights that extension cords should not be overloaded and should not be used as a substitute for permanent wiring, which is highly relevant when people try to adapt NEMA connectors using the wrong cord solutions.

Ground, Neutral, and Why Some Connectors Look Similar but Aren’t Equivalent

Many nema connector charts distinguish connectors by whether they include a neutral and a ground, and by how many conductors are involved. Beginners don’t need to memorize conductor theory to use the chart safely, but they do need to recognize that “it powers on” is not the same as “it’s correctly wired.”

NFPA’s grounding and bonding overview (tied to NEC Article 250) is a good starting point for understanding why grounding is essential for safety and why correct bonding practices matter.

In real-world terms, grounding provides a safer fault path, and neutral is part of how many AC systems complete the circuit. Whether your connector includes one, both, or neither changes what it can safely supply.

Locking vs Non-Locking: When You Actually Need Twist-Lock

If a cord could be pulled, bumped, or vibrated loose, a locking connector can prevent unwanted shutdowns and arcing risks. This is why charts for locking connectors are common in industrial contexts and portable power workflows. Locking charts often show configurations like L5, L6, and L14 as common families, with L14-30 being a very frequent generator/transfer-switch style configuration.

If you’re choosing between a straight-blade and locking option for the same electrical rating, your deciding factors usually come down to movement, vibration, and the impact of an accidental unplug. In a calm indoor office environment, non-locking is often fine. In a workshop, a jobsite, or a rack environment where cable movement is real, locking becomes far more attractive.

Beginner Scenarios: How You Use a NEMA Connector Chart in Real Life

Consider a small home workshop where a new tool lists “240V, 20A.” Without a chart, beginners often guess and buy the wrong receptacle or cord. With a nema connector chart, you can identify likely families that match 240V and 20A and then confirm what your tool actually ships with and what your circuit provides.

In a generator scenario, many users see an L14-30 connector and don’t understand what it means. A chart clarifies that it’s a locking configuration commonly used for generator outputs and transfer switch inputs in many setups, and that it’s associated with a 125/250V class and 30A rating on common references.

In a small IT closet, you might buy a UPS and discover the plug won’t fit the outlet you have. A chart helps you identify the plug type, confirm its rating, and decide whether you need a different circuit, a different UPS model, or a properly installed receptacle change.

Common Mistakes Beginners Make

One common mistake is relying on adapters to “convert” between connectors without fully understanding voltage, current, and grounding implications. Another is using extension cords as if they were permanent wiring, especially when a connector mismatch makes the “right” solution inconvenient. ESFI’s safety guidance is clear that extension cords are temporary solutions and should not replace permanent wiring, and overloading is a major hazard.

A third mistake is mixing up look-alike configurations. Some plugs look similar at a glance, especially to someone new, but are not interchangeable. The chart exists to prevent exactly that kind of error, so it’s worth taking a minute to confirm the code, not just the shape.

Practical Tips for Choosing the Right NEMA Connector Without Overthinking It

Start by reading your equipment nameplate or manual for voltage and amperage, then match that information to the chart family and configuration. Confirm whether the device expects a neutral and ground, and confirm whether your installation provides those conductors. When the setup involves generators, transfer equipment, or any change to building wiring, treat a licensed electrician as part of the process rather than a last resort, because code and safety requirements can vary by jurisdiction even when the connector standard is consistent. NEMA’s dimensional standards exist to keep devices consistent, but installation and code compliance live in the NEC/local-code world.

FAQ: NEMA Connector Chart for Beginners

What is a NEMA connector chart?

A nema connector chart is a diagram or table that maps NEMA plug and receptacle configurations to their typical voltage class, amperage rating, and physical blade pattern so you can identify compatibility safely.

What does “5-15” mean on a NEMA chart?

On common reference charts, “5-15” identifies a configuration family and a 15-amp rating that corresponds to a widely used 125V grounded household-style connector pattern.

What does the “L” mean in NEMA connectors?

The “L” denotes a locking or twist-lock configuration, designed to reduce accidental unplugging in environments where cords can be bumped or vibrated. Locking reference charts commonly list families like L5, L6, and L14.

Are NEMA connectors used worldwide?

NEMA connectors are primarily a North American standard system. Many other regions use different plug standards, so NEMA charts are most relevant for U.S./Canada-style installations and equipment built for those markets.

Is it safe to use adapters to make a plug fit?

It depends on what the adapter does electrically, not just physically. Many “make it fit” solutions can bypass grounding or create overload risk. Safety guidance emphasizes avoiding overload and avoiding treating temporary cord solutions as permanent wiring.

Conclusion: Why a NEMA Connector Chart Makes Electrical Work Safer

A nema connector chart turns confusing plug shapes and cryptic codes into a clear, safety-first decision process. When you use the chart properly, you reduce the chances of voltage mismatch, overheating from incorrect current assumptions, and grounding mistakes that can turn minor errors into major hazards. Pair the chart with reputable references, use NEMA’s wiring device standards as your backbone, and treat grounding and safe wiring practices as essential, not optional.