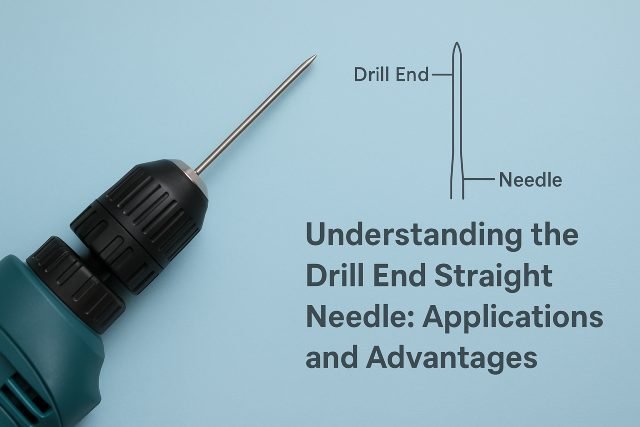

Introduction to the Drill End Straight Needle

When it comes to precision and efficiency in various industrial applications, the drill end straight needle stands out as a remarkable tool. This innovative device combines simplicity with functionality, making it an essential item for professionals across multiple fields. Whether you’re in manufacturing, construction, or even medical settings, understanding this specialized instrument can elevate your work quality and streamline processes. In this blog post, we’ll explore what makes the drill end straight needle a go-to choice for many industries and how you can leverage its unique features to enhance your projects. Get ready to dive into the world of drilling tools that not only meet but exceed expectations!

Applications of the Drill End Straight Needle in Different Industries

The drill end straight needle has found its place in various industries due to its unique design and functionality. In the medical field, it is widely used for suturing tissues during surgical procedures, ensuring accurate penetration and minimal trauma.

In the textile industry, these needles facilitate precise sewing of heavy fabrics. Their sharp tapered ends allow them to easily pierce multiple layers without causing fraying or damage.

The automotive sector also benefits from this tool. It enables efficient stitching of upholstery materials, contributing to both aesthetics and durability in vehicle interiors.

Additionally, woodworking applications utilize drill end straight needles for tasks like joinery and fastening wood pieces together seamlessly. Their versatility makes them suitable for a range of projects across different sectors.

Advantages of Using a Drill End Straight Needle

The drill end straight needle offers several notable advantages that make it a preferred choice in various applications. Its unique design allows for efficient penetration into tough materials, ensuring a clean entry with minimal resistance.

One of the key benefits is precision. The sharp tip aids in accurate placement and reduces the risk of damaging surrounding structures during use. This feature is particularly valuable in delicate operations where every millimeter counts.

Moreover, these needles are versatile across multiple industries — be it medical, automotive, or manufacturing. Their adaptability makes them indispensable tools for professionals seeking reliability and performance.

Durability also stands out as a significant advantage. Made from high-quality materials, they withstand repeated use without losing effectiveness. This longevity translates to cost savings over time while maintaining operational efficiency throughout their lifespan.

How to Choose the Right Drill End Straight Needle for Your Needs

Choosing the right drill end straight needle starts with understanding your specific application. Consider factors such as material type, thickness, and the precision required for your task.

Next, look at the gauge of the needle. A finer gauge works best for delicate applications, while a thicker needle provides sturdiness for tougher materials.

Evaluate the length too; longer needles can reach deeper areas but may be less maneuverable in tight spaces.

Don’t forget about compatibility with your existing tools or machines. Ensure that any chosen needle fits seamlessly to avoid operational hiccups.

Consider manufacturer reviews and recommendations to guide you toward quality options tailored to your needs. This thorough approach will help ensure optimal results and longevity from your drill end straight needle choice.

Tips for Proper Use and Maintenance of a Drill End Straight Needle

To ensure the longevity of your drill end straight needle, start with regular inspections. Check for any signs of wear or damage before each use. This simple step can prevent mishaps during critical tasks.

Proper cleaning is essential after every project. Use a soft brush to remove debris and lubricate the needle lightly to keep it functioning smoothly. Avoid harsh chemicals that could degrade the material.

When storing, keep the needle in a protective case or designated area away from moisture and extreme temperatures. This will help maintain its integrity over time.

Using appropriate techniques while working will minimize unnecessary strain on the tool. Ensure you’re applying even pressure throughout your task for optimal results.

Don’t hesitate to consult manufacturer guidelines specific to your drill end straight needle. These resources offer valuable insights tailored to enhance performance and durability.

Frequently Asked Questions About Drill End Straight Needles

Many users have questions about the drill end straight needle and its capabilities. One common inquiry is whether it can be used on various materials. The answer is yes; these needles are versatile and effective across multiple substrates.

Another frequent question involves the differences between drill end straight needles and standard sewing needles. Drill end needles feature a specialized tip designed to create clean holes, which enhances efficiency in specific applications.

People also wonder how to determine the right size for their projects. It depends on factors like material thickness and required hole diameter. Always consider your project’s needs when selecting a needle.

Some may ask about maintenance practices. Keeping the needle clean and ensuring it’s stored properly will extend its lifespan significantly, making it a reliable tool in your toolkit.

Conclusion: The Versatility and Efficiency of the Drill End Straight Needle

The drill end straight needle stands out as a vital tool across various industries. Its design allows for precision and efficiency, making it an essential component in tasks that require accuracy. From medical applications to manufacturing processes, its versatility is unmatched.

Using the right drill end straight needle can significantly enhance productivity and quality. The advantages of this tool — from reduced risk of damage to materials to improved workflow — cannot be overstated. When professionals choose the correct type for their specific needs, they are investing in better outcomes.

Proper maintenance ensures longevity and consistent performance. By keeping these needles in top shape, users can rely on them time after time without worry.

As demand for effective tools grows, understanding how to utilize items like the drill end straight needle becomes increasingly important. This knowledge empowers users across sectors, enhancing both their skills and results with every project undertaken.