When people search for copper tube diameter, the biggest surprise is that a tube’s labeled size is not always its real measured diameter. A “½ inch copper tube,” for example, does not always measure ½ inch across, because copper tubing can be sized by nominal measurement, outside diameter, or inside diameter depending on the application and standard.

This guide explains copper tube diameter in both mm and inches, compares plumbing copper and refrigeration copper, clarifies OD vs ID vs nominal sizing, and includes practical conversion tables that are useful for installers, engineers, and DIY users. You will also learn how standards such as ASTM B88 and EN 1057 affect sizing choices, and how to avoid expensive mistakes caused by mismatched fittings.

What Is Copper Tube Diameter?

Copper tube diameter refers to the measured size of copper tubing, usually expressed as outside diameter (OD), inside diameter (ID), or nominal size. Outside diameter is the most important measurement for fittings and compatibility. Inside diameter matters most for flow rate and pressure loss, and it depends on the tube’s wall thickness. Nominal size is commonly used in plumbing systems and does not always match the actual diameter. Many ASTM B88 copper water tubes use nominal sizing where the actual outside diameter is usually 1/8 inch larger than the nominal size.

Copper Tube Diameter Basics: OD vs ID vs Nominal Size

Copper tubing is easiest to understand once you separate its three sizing systems. Outer diameter (OD) is the physical measured outside width of the tube. Inner diameter (ID) is the open space inside the tube and determines how much water or refrigerant can flow through. Nominal size is a naming convention used mainly in plumbing, where the size label does not reflect the true measured OD.

In ASTM B88 plumbing copper, the tube is typically sold using nominal size, while the OD is larger than the nominal measurement. This is why ½ inch copper often measures 5/8 inch OD instead of ½ inch.

Copper Tube Diameter in Plumbing vs HVAC

The biggest reason copper tube sizing confuses people is that plumbing and refrigeration systems do not use the same approach. Plumbing copper tube under ASTM B88 is labeled by nominal size, but its outside diameter is fixed and standardized at a higher value. ACR copper tubing, which is used in air conditioning and refrigeration, is typically sold by actual OD, which is why sizes like ¼ inch, ⅜ inch, and ½ inch usually refer to the true outside diameter.

That means if you accidentally buy plumbing copper for refrigeration, your flare fittings may not fit properly, and this can cause leaks and installation failure. ACR copper sizing references show the OD-based sizing used in refrigeration applications.

Copper Tube Diameter Chart

The table below shows common copper tube sizes and their typical outside diameter conversion in inches and millimeters. This is particularly useful for comparing nominal plumbing copper sizes with actual OD measurements used in fittings.

| Nominal / Trade Size | Actual OD (in) | Actual OD (mm) |

|---|---|---|

| 1/4″ (nominal) | 3/8″ | 9.52 mm |

| 3/8″ | 1/2″ | 12.70 mm |

| 1/2″ | 5/8″ | 15.88 mm |

| 5/8″ | 3/4″ | 19.05 mm |

| 3/4″ | 7/8″ | 22.23 mm |

| 1″ | 1-1/8″ | 28.58 mm |

| 1-1/4″ | 1-3/8″ | 34.93 mm |

| 1-1/2″ | 1-5/8″ | 41.28 mm |

| 2″ | 2-1/8″ | 53.98 mm |

This OD relationship is aligned with ASTM B88 copper tube sizing conventions.

Copper Tube Diameter by Type: K vs L vs M (Wall Thickness)

In plumbing copper, the outside diameter remains constant for a given nominal size, but the inside diameter changes depending on wall thickness. This is where Type K, Type L, and Type M matter.

Type K is the thickest copper tubing and is often used for underground or higher-pressure applications. Type L is a mid-thickness tube and is one of the most common choices for indoor plumbing. Type M is the thinnest, typically used in residential systems where pressure demands are lower.

ASTM B88 tables show how each type has different wall thickness values and therefore different inside diameters for the same nominal tube size.

Copper Tube ID Calculation

Inside diameter can be calculated easily when you know the OD and wall thickness. The formula is: ID = OD − (2 × wall thickness).

For example, if the tube OD is 5/8 inch and its wall thickness is 0.040 inch, the ID becomes 0.625 − (2 × 0.040) = 0.545 inch. This calculation is important for designing systems where flow capacity matters, including heating circuits and water distribution lines.

Copper Tube Diameter Standards: ASTM B88 vs EN 1057

Copper tube sizing is strongly influenced by regional standards. In North America, ASTM B88 dominates plumbing copper tubing. In Europe and many international markets, EN 1057 is widely used.

ASTM B88 typically uses nominal sizing and fixed OD rules. EN 1057 usually describes copper tubing using its actual OD in mm and wall thickness. For example, “15 × 1.0 mm” means a tube with a 15 mm outside diameter and a 1.0 mm wall thickness. EN 1057 charts list common OD ranges such as 10 mm, 12 mm, 15 mm, 18 mm, 22 mm, and higher sizes for commercial use.

Common EN 1057 Copper Tube Diameters (mm)

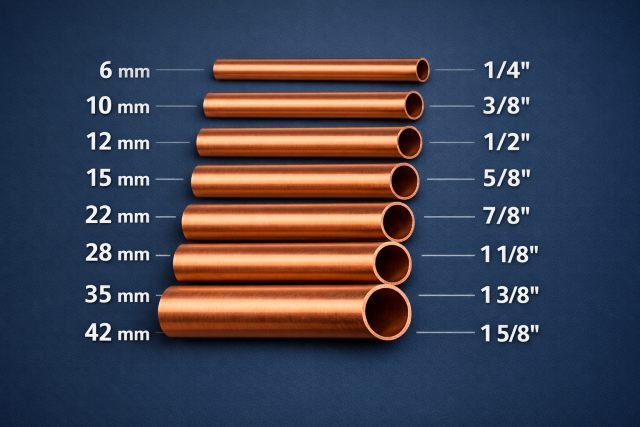

EN 1057 makes sizing clearer because the outside diameter is listed directly. Many plumbing and heating systems use 10 mm, 12 mm, 15 mm, 18 mm, and 22 mm diameters, while larger installations and commercial distribution networks often use 28 mm, 35 mm, 42 mm, and 54 mm. Engineering references confirm these OD ranges and highlight how wall thickness varies by application.

ACR Copper Tube Diameter in Inches and mm (Refrigeration Tubing)

ACR copper tubing is used in air conditioning, refrigeration, and heat pump linesets. Unlike plumbing copper, ACR tubing is usually labeled by actual OD, which makes it more straightforward when matching flare fittings.

Common ACR outside diameters include ¼ inch (6.35 mm), ⅜ inch (9.52 mm), ½ inch (12.70 mm), ⅝ inch (15.88 mm), ¾ inch (19.05 mm), and ⅞ inch (22.23 mm). ACR sizing references publish these OD standards for refrigeration applications.

Copper Tube Size vs Copper Pipe Size (Important Difference)

Copper tube and copper pipe are often used interchangeably in everyday speech, but they do not always follow identical sizing systems. Copper tubing is usually sized by OD or nominal tube conventions, while piping systems in other materials often follow nominal pipe size (NPS) systems that use a different OD relationship. This difference matters when fittings are involved because a copper “tube” fitting may not match a “pipe” system fitting of the same labeled size.

Practical Selection Guide: How to Choose the Right Copper Tube Diameter

The best way to choose the correct copper tube diameter is to confirm the system type and the standard it follows. Plumbing installations usually follow ASTM B88, where sizing is nominal and OD is standardized. HVAC and refrigeration systems typically follow ACR tubing rules, where sizing matches actual OD.

Fitting type matters too. Compression fittings require correct OD matching. Solder fittings typically work with nominal tube standards. Flare fittings are common in refrigeration and require ACR OD matching.

Pressure and environmental conditions determine whether Type K, L, or M is appropriate. Flow requirements determine whether you should prioritize a larger inside diameter. These factors together prevent leaks, poor performance, and rework.

Real-World Mistakes and How to Avoid Them

A common plumbing mistake happens when someone buys “½ inch copper” and expects it to fit a ½ inch OD compression coupling. In ASTM B88 systems, ½ inch copper is nominal, and its OD is actually 5/8 inch, which leads to fitting mismatch. ASTM B88 references help clarify this size relationship.

A frequent HVAC mistake occurs when a technician uses plumbing copper instead of ACR copper. For example, refrigeration systems often require ¼ inch and ⅜ inch OD tubing. If the installer uses plumbing tube labeled ⅜ inch nominal, its OD becomes ½ inch and flare fittings will not fit. ACR sizing references highlight the OD-based conventions used in HVAC.

Copper Tube Diameter Tolerances (Why Exact Isn’t Always Exact)

Copper tube standards include diameter and wall thickness tolerances because manufacturing is never perfectly exact. This matters most in press-fit systems, compression fittings, brazed joints, and precision applications. ASTM B88 dimension tables include tolerance guidance that helps ensure compatibility across manufacturers.

Copper Tube Diameter Conversion Tips (Inches ↔ mm)

Copper tube diameter conversion is straightforward because 1 inch equals exactly 25.4 mm. Some common conversions include ¼ inch at 6.35 mm, ⅜ inch at 9.525 mm, ½ inch at 12.7 mm, ⅝ inch at 15.875 mm, ¾ inch at 19.05 mm, and ⅞ inch at 22.225 mm. EN 1057 references also use OD × wall thickness formats that make mm-based sizing simpler for many systems.

Copper Tube Diameter FAQ

What is the copper tube diameter for 1/2 inch copper?

In ASTM B88 plumbing copper, ½ inch is a nominal size and the actual outside diameter is typically 5/8 inch, which equals 15.88 mm.

Is copper tube measured by OD or ID?

Copper tube can be measured by OD or nominal size depending on the system. ACR copper tubing is generally sized by actual OD, while plumbing copper under ASTM B88 uses nominal sizing rules.

What does 15 × 1.0 mm mean in copper tubing?

In EN 1057 conventions, 15 × 1.0 mm means the tube has a 15 mm outside diameter and a wall thickness of 1.0 mm.

What is the difference between Type L and Type M copper tube?

Type L has thicker walls than Type M. This increases durability but slightly reduces inside diameter and flow space. ASTM B88 tables show the exact wall thickness differences by size.

Conclusion: Copper Tube Diameter in mm & Inches Made Simple

Choosing the correct copper tube diameter is essential for proper fitment, safe operation, and leak-free performance. The most important takeaway is to confirm whether your system uses nominal sizing or actual OD sizing. Plumbing copper under ASTM B88 typically uses nominal sizes where the outside diameter is larger than the name suggests, while ACR copper tubing is usually labeled by true OD for direct compatibility with refrigeration fittings. EN 1057 is often simpler because it lists OD in millimeters and includes wall thickness as part of the designation.

When you verify OD vs ID, match the correct standard, and account for wall thickness type, you eliminate the most common causes of sizing mistakes and installation rework. That is the fastest way to save time, reduce material waste, and ensure your copper system performs exactly as designed.